linkage parts in a hardness tester|hardness testing methods pdf : ODM For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower . An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an .

{plog:ftitle_list}

A description of the autoclave process, including pertinent information such as cycle type (e.g., saturated steam, water immersion, and water spray), cycle parameters and performance

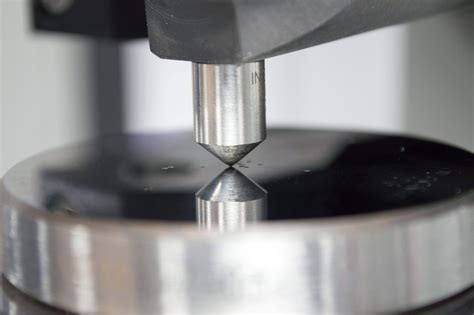

For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower .There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an . For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower levels. It's best to have blocks for the hardness level you want to test, and check it regularly.There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. 2 Brinell Hardness.

Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating conditions. The basic components of a nano hardness tester can be divided into several parts, including the control system, moving coil system, loading system, and indenter. Diamond indenters, which are typically triangular cones or four-edge dimensions, are commonly used.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.The Rockwell hardness test calculation (HR) is made by measuring the depth of an indentation made with a diamond or tungsten carbide ball. Indenters. The Rockwell hardness test utilizes 1 of 5 different indenters: Diamond cone. Tungsten ball in sizes 1/16", 1/8", 1/4", or 1/2" Main loads.

stainless steel centrifugal pump

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials hardness. There are several different tests used to display the hardness of materials including, Brinell . Starrett Durometers are precision instruments used for measuring the hardness of rubber, plastics, and other elastomers. With a variety of models available, including Type A, B, C, D, O, and OO testers, these instruments provide accurate and reliable results.The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop).

For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower levels. It's best to have blocks for the hardness level you want to test, and check it regularly.There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. 2 Brinell Hardness.Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating conditions. The basic components of a nano hardness tester can be divided into several parts, including the control system, moving coil system, loading system, and indenter. Diamond indenters, which are typically triangular cones or four-edge dimensions, are commonly used.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.

The Rockwell hardness test calculation (HR) is made by measuring the depth of an indentation made with a diamond or tungsten carbide ball. Indenters. The Rockwell hardness test utilizes 1 of 5 different indenters: Diamond cone. Tungsten ball in sizes 1/16", 1/8", 1/4", or 1/2" Main loads.

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials hardness. There are several different tests used to display the hardness of materials including, Brinell . Starrett Durometers are precision instruments used for measuring the hardness of rubber, plastics, and other elastomers. With a variety of models available, including Type A, B, C, D, O, and OO testers, these instruments provide accurate and reliable results.

what is a hardness test

Good laboratory practice examples: Find out if your culture media sterilization procedure is consistently sterilizing your media.

linkage parts in a hardness tester|hardness testing methods pdf